Cosmetic peptides have emerged as an important ingredient in countless skincare products, especially for those marketed towards preserving a youthful appearance. Since peptides are active in many body systems, it is not surprising that they play several roles in the health and maintenance of the skin.

CEM & AmbioPharm’s partnership allows for an ideal production of peptides for cosmetics. Using CEM’s unique peptide synthesis technology allows for a greener CMR free (Carcinogenic, Mutagenic, and Reprotoxic free) production process to be utilized. AmbioPharm’s U.S. based Manufacturing site has completed US FDA Inspections and can support production of the simplest to most complex cosmetic peptide ingredients.

N-butylpyrrolidinone (NBP; TamiSolve NxG-PS) has demonstrated the ability to work well as a greener alternative apolar diprotic solvent. It’s use in microwave SPPS is easier than traditional methods since the elevated temperature reduces its relatively high viscosity.

Additionally, CEM has developed a unique solvent mixture that is ideal for microwave peptide synthesis1. This is based on the use of anisole and N-butylpyrrolidinone that provides ideal properties for completely replacing traditional solvents. This solvent system has been demonstrated on a range of difficult peptides and provides favorable toxicity, reduced viscosity, and low overall cost.

Learn More (on CEM website)

View Data (on CEM website)

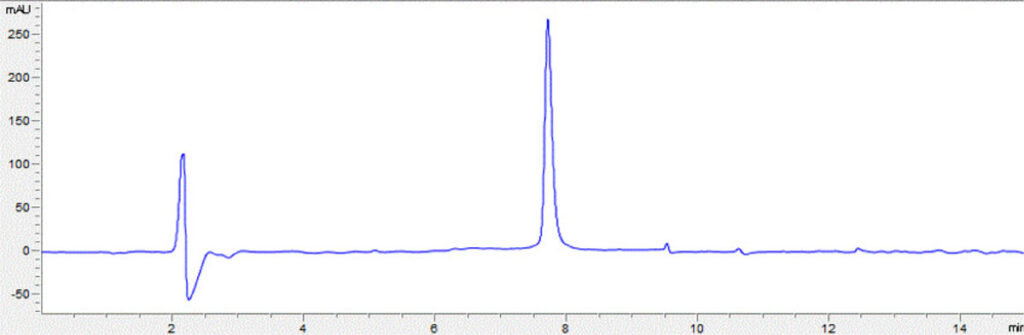

Synthesis of a 75mer Peptide free of any CMR Solvent

VVEAGGWVTTIVSILTAVGSGGLSLLAAAGRESIKAYLKKEIKKKGKRAVIAWMAKEFGIPAAVAGTVLNHVKKK-NH2

1US 11,014,959; WO2019241586A1